From Discarded fruits to your everyday luxury

Deep Dive

What is Leather by Fruit & Plant Fibers?

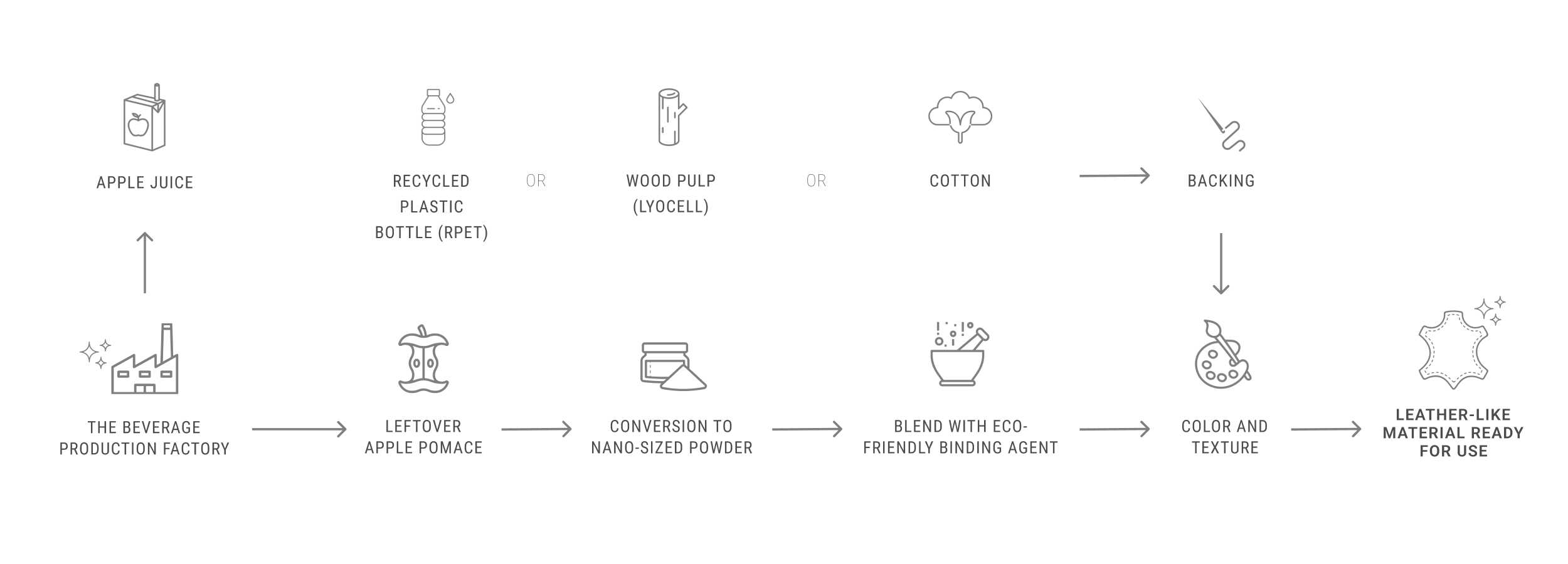

HOw is Apple Leather made

When apples are processed for juice, about 70-75% of the apple goes into the juice, leaving the remaining 25-30% as pomace.

In commercial productions, apple pomace usually ends up in the landfill and quickly starts to release methane, an extreme potent green house gas, due to the high moisture level and lack of oxygen.

However, the pomace is full of fibers that can be further utilized.

With production partners, we collect the pomace and dehydrate it. The dried product is then mixed with binding agents and laminated on recycled, plant-based fabric.

The Environmental Impact

1Kg of Apple pomace upcycled equals to 2.5kg of CO2 emission avoided Under Current production level

1 Gala Puzzle Cardholder upcycles pomace waste from 25-30 apples

Water-based solvent & Zero emissions of hazardous chemicals to the Environment

HOw is Cactus Leather Made

We work with Desserto®, a Mexico-based material innovator, to bring you cactus leather.

On its sustainably operated Nopal farm, mature leaves are harvested of without damaging the plant itself, enabling repeat harvest every 6-8 months from the same plants.

The harvested leaves are used for human consumption, animal stock and the production of cactus leather, maximizing the utilization of every harvest.

The Environmental Impact

The farm absorb 8100 tons of CO2, while generate only 15.3 tons annually

It takes about 3 cactus leaves to create one linear meter of Cactus leather

Biodegradable under anaerobic thermophilic conditions

HOw is Mango Leather Made

We work with Fruitleather Rotterdam, a Netherland-based material lab, to bring you mango leather.

Mangoes sold in countries like Netherland experience very high waste rate because the fruit is mostly imported and have a very short shelf life. Once the fruit is bruised or starting to go bad, it's unlikely to be sold and ends up be thrown out. However "rotten" mangoes are a great starting point given their high sugar and fiber level.

Once the discarded mangoes are collected, they are boiled down and baked into sheets in a process similar to making fruit rollups, with help of some natural additives as biding agents and GOTS-certified organic cotton material as backing.

Material Highlights

100% vegan & Cruelty Free

One cardholder upcycles 1.5 discarded MANGOES

Small batch production / seasonal as the fruit

Due to high seasonality, mango collection is only available in summer time. Subscribe to our weekly newsletter and get notified.

WE work with Peel Lab & Bring you Pineapple Leaf Leather

Peta certified vegan

180kg of pineapple leaves upcycled to date

Versatile & Resilient Material

Deep Dive

It takes Much More

...and most brands will not disclose these

Binding Agent

No plant-based material can perform as leather without binding agent.

Natural additives, water-based solvent and/or biobased polymer, are used to ensure performance while keeping the materials PVC-free.

Backing

We prioritize using sustainably sourced, plant-based backing materials such as organic cotton as much as possible.

Recycled materials are used when the plant-based options are not available.

Lining Material

We prioritize using sustainably produced, plant-derived materials or recycled materials for lining.

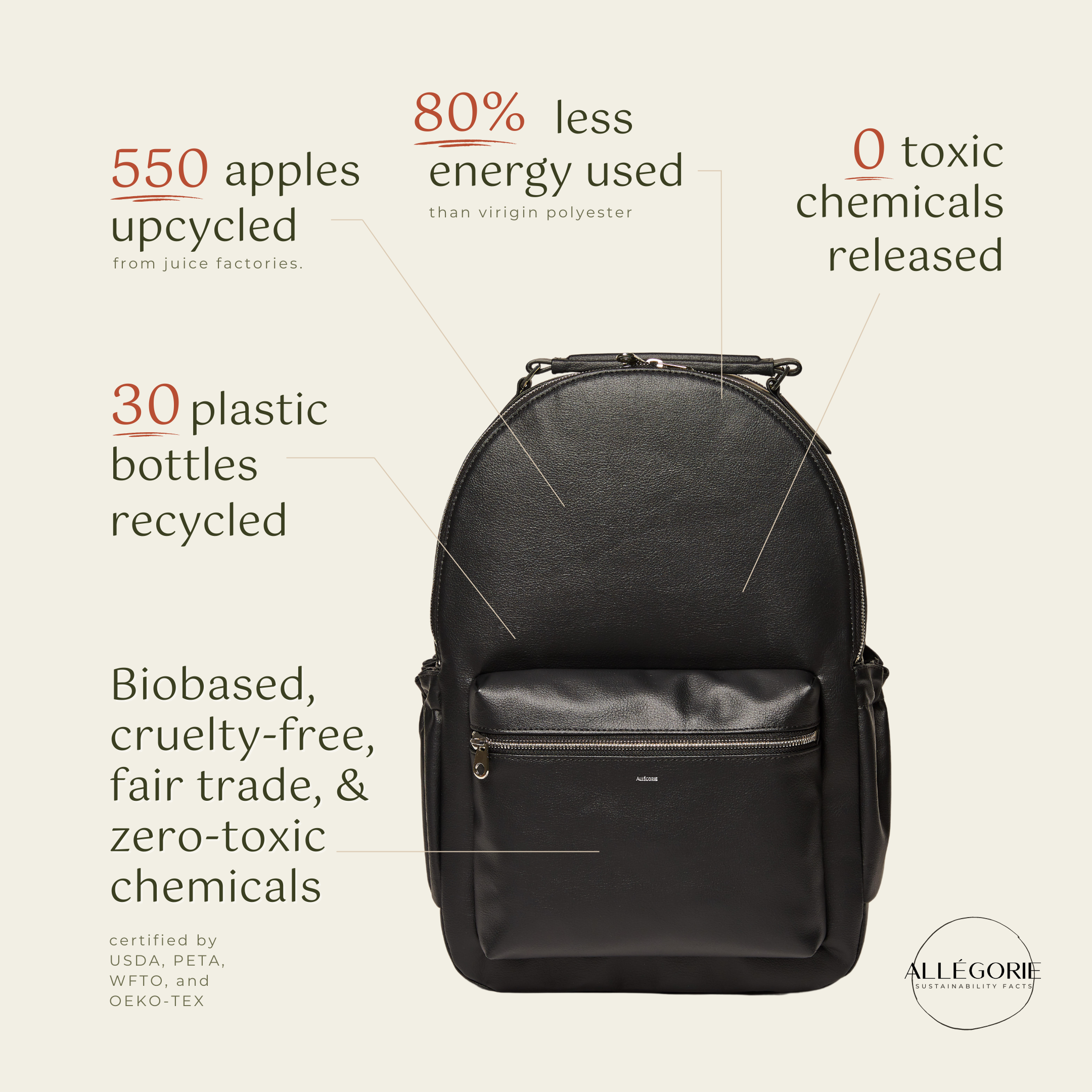

We currently use a mixture of plant-based fiber and recycled plastic bottles for lining materials.

...and much more

For example, it takes 80% less energy to make the lining materials we use vs. producing virgin polyester.

We are committed to keep our entire supply chain sustainable & responsible.